Productos calientes

TB-NE Series OEM Custom Roller Chain Bucket Elevator Lifting Conveyor for Bulk Material Lifting

TB-NE type plate chain bucket elevator is suitable for lifting lump coal, gravel, ore, pebbles and other grinding and polishing materials with a specific gravity of no more than 2t/m3. It adopts gravity discharge, with plate chain sleeve roller chain as the traction part.

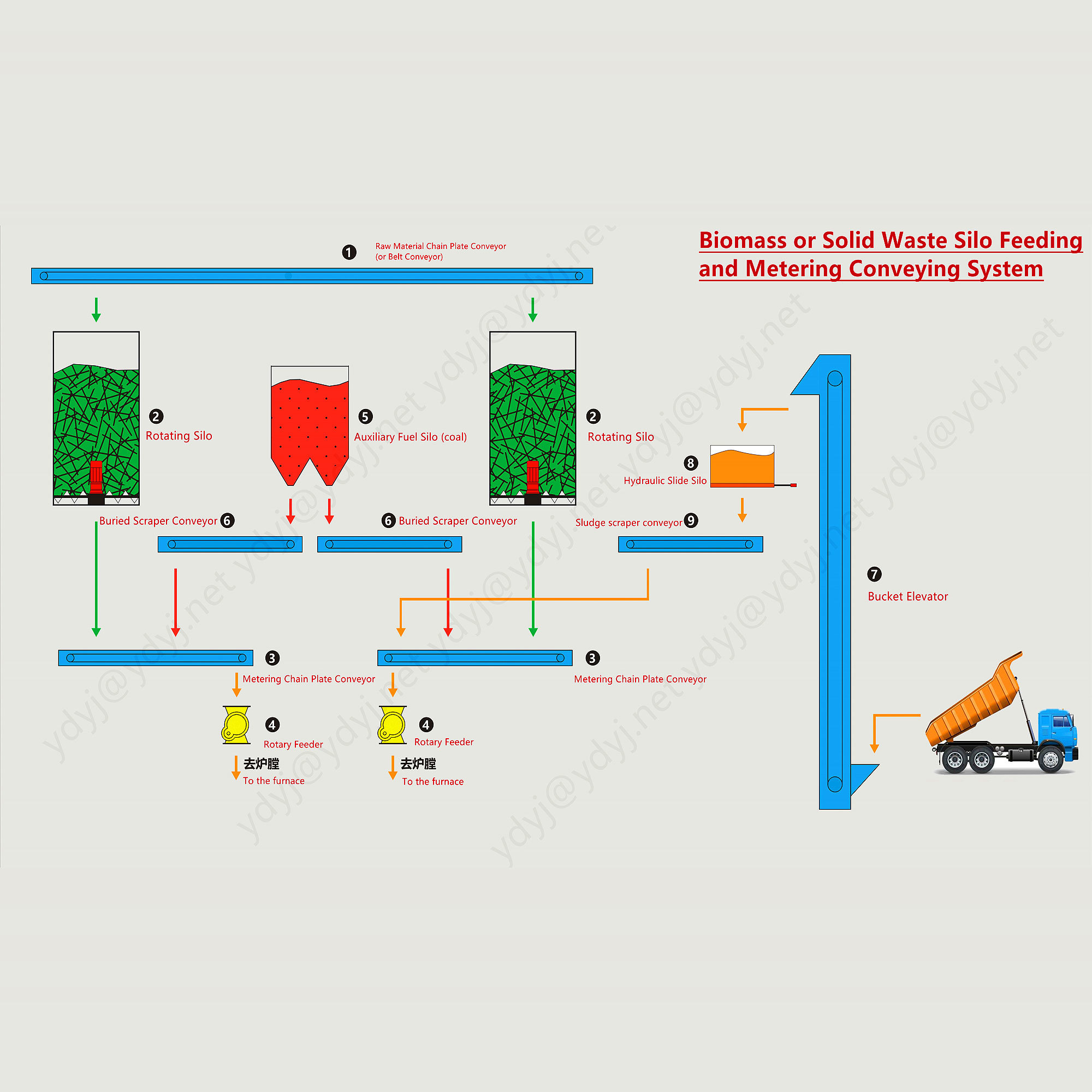

OEM Custom Refuse-derived Fuel Arm Rotary Silo Discharge System for Solid Fuel Feeding System

The elastic and flexible scraper rotates around the central vertical axis under the drive device to scrape the material into the discharge screw at the bottom of the warehouse, while preventing the material from arching the bridge in the plant. The discharge screw realizes the control of discharge amount through frequency conversion speed regulation, the discharge process is uniform, continuous and stable, and the energy consumption is low.

Rotation and revolution rotary discharge system is a new and efficient storage and discharge equipment, which is suitable for all kinds of easily bridged mixed materials in biomass power plants and domestic waste power plants.

Shaftless screw conveyor is a kind of completely enclosed equipment that relies on the spiral body to rotate and transport materials without a central shaft, and has good environmental protection performance. It is composed of spiral blades and housing, spiral blades can rotate the material from one port to another port, it has no central shaft, so the material is not easy to block, the discharge port is not blocked, while reducing the time and cost of maintenance and cleaning. It is suitable for conveying powdery, granular, flake and fibrous materials, widely used in chemical, food, medicine, metallurgy, building materials and other transportation of all kinds of viscous materials.

GX series screw conveyor has strong adaptability, flexible arrangement of import and export positions, low noise and easy operation and maintenance. It can be used for horizontal cargo inclined transport of various powder, granular and small block materials, such as pulverized coal, flour, cement, sand, bulk grain, coal, etc.the working environment temperature is from -20 degrees to +50 degrees, and the material temperature is below +200 degrees.

OEM Factory Custom Steel TD Belt Bucket Elevator Conveyor Manufacturer

TD belt bucket elevator is suitable for lifting powdery, granular and small block low grinding cut materials with packing density less than 1.5t/m3. It has many specifications, large throughput, high lifting height, smooth operation and long life.

VIEW MORE +TH ring chain bucket elevator is suitable for lifting wet sand, fertilizer, alkali powder, clay and other materials with high humidity, strong viscosity and difficult to throw; Lifting gravel, coal, cement raw materials, slag and cement are relatively dry and loose, easy to throw out materials. Material temperature does not exceed 250 degrees.

VIEW MORE +TZD type efficient special bucket elevator is suitable for conveying grain and other loose materials, used in grain station, port industry. It has the characteristics of large conveying capacity, high lifting height and high speed.

VIEW MORE +Professional Customized Rectangular Flat Bottom Silo Discharge System for Sludge Gypsum Wood Cement

Rectangular flat bottom silo discharge system is used to discharge difficult to flow bulk materials stored in flat bottom rectangular silo. Compared with the design of the bucket bottom, the flat bottom design of the silo has many advantages, such as simple construction and full use of space. The rectangular silo slide frame has quite good flexibility in the selection of structure, combination mode and discharge position, and can be reliably and accurately distributed, so it can fully meet the various special requirements of users, and can be used for material storage silo, automobile transfer station, or recycling station. According to the user's different requirements for the discharge position, it can push the material to one end of the silo, or to the center of the silo, and then be sent out by the discharge screw, scraper conveyor or other conveyor.

VIEW MORE +