Productos calientes

TB-NE Series OEM Custom Roller Chain Bucket Elevator Lifting Conveyor for Bulk Material Lifting

TB-NE type plate chain bucket elevator is suitable for lifting lump coal, gravel, ore, pebbles and other grinding and polishing materials with a specific gravity of no more than 2t/m3. It adopts gravity discharge, with plate chain sleeve roller chain as the traction part.

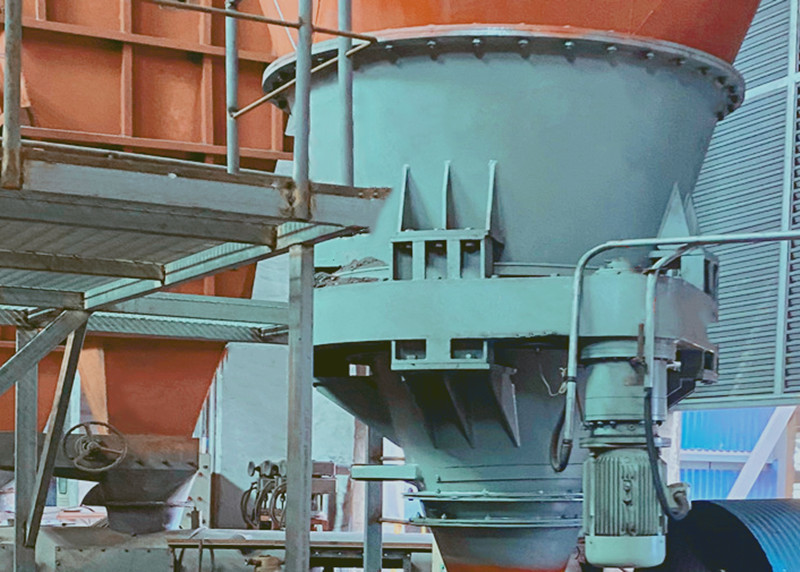

OEM Custom Refuse-derived Fuel Arm Rotary Silo Discharge System for Solid Fuel Feeding System

The elastic and flexible scraper rotates around the central vertical axis under the drive device to scrape the material into the discharge screw at the bottom of the warehouse, while preventing the material from arching the bridge in the plant. The discharge screw realizes the control of discharge amount through frequency conversion speed regulation, the discharge process is uniform, continuous and stable, and the energy consumption is low.

Rotation and revolution rotary discharge system is a new and efficient storage and discharge equipment, which is suitable for all kinds of easily bridged mixed materials in biomass power plants and domestic waste power plants.

Shaftless screw conveyor is a kind of completely enclosed equipment that relies on the spiral body to rotate and transport materials without a central shaft, and has good environmental protection performance. It is composed of spiral blades and housing, spiral blades can rotate the material from one port to another port, it has no central shaft, so the material is not easy to block, the discharge port is not blocked, while reducing the time and cost of maintenance and cleaning. It is suitable for conveying powdery, granular, flake and fibrous materials, widely used in chemical, food, medicine, metallurgy, building materials and other transportation of all kinds of viscous materials.

GX series screw conveyor has strong adaptability, flexible arrangement of import and export positions, low noise and easy operation and maintenance. It can be used for horizontal cargo inclined transport of various powder, granular and small block materials, such as pulverized coal, flour, cement, sand, bulk grain, coal, etc.the working environment temperature is from -20 degrees to +50 degrees, and the material temperature is below +200 degrees.

OEM Three-way Discharge Gate Valve Diverter Gate Three Way Shunt Valve

The three-way valve is used to realize the two-way switching and two-way diverting of materials. It is suitable for all kinds of ore, coal, coke, ash, chemical products and other bulk materials with a specific gravity of less than or equal to 2.5t/m3.

VIEW MORE +MX alkali conveyer is specially used for conveying corrosive materials, strong adhesion, high humidity, small particle size and strong suspension materials in the chemical industry, and is widely used in soda ash, fertilizer, glycyrrhizin, para-ester, diacetonitrile, TCP and other chemical fields.

VIEW MORE +MSD series coal scraper conveyor is suitable for conveying coal before coal mill in power station, coal conveying in circulating fluidized bed boiler, cement clinker and manganese ore particles and other large size, large density material conveying, its speed is low and adjustable, by adjusting the height of the material layer to control the feed amount. This series has a total of 5 models, the maximum throughput can reach 120t/h.

VIEW MORE +Z Shaped OEM Wear-resistant Chain Conveyor Drag Chain Scraper Conveyor or Elevator for Sludge

MZG series sludge special scraper conveyor or Elevator is mainly used for waste power plant, coal-fired coupled power plant and other dry sludge into the furnace automatic conveying system, with high automation, good equipment sealing, good conveying stability. Improve the economy, reliability and rationality of system operation. Layout is divided into type I, type C, type S and type Z.

VIEW MORE +The specially designed discharge arm rotates around the central vertical axis under the drive device. The discharge arm rotates and cuts at the bottom of the silo, scraping the material at the bottom of the silo to the central discharge port. The discharge arm can not only ensure that the material will not accumulate and consolidate at the bottom of the silo and the outlet during the discharge process, but also can remove the material on the wall and the bottom of the silo. The discharge quantity is controlled by frequency conversion speed regulation, the discharge process is uniform, continuous and stable, and the energy consumption is low.

VIEW MORE +Pneumatic gate is mainly composed of frame, ram, pneumatic components, etc., using compressed air as the driving power source, through the control box on the back and forth switch and stop switch and can control the ram for horizontal reciprocating movement, to achieve the purpose of valve opening and closing, widely used in building materials, metallurgy, mining and other industries dust material flow control pipe. It is the ideal equipment for controlling the flow of dust materials. Simple structure, light weight, flexible operation, easy assembly and disassembly, high strength, good performance, long service life; The maintenance is convenient and fast, which greatly reduces the intensity of human labor.

VIEW MORE +The cone silo bottom rotary discharge silo is installed in the cone bottom of the silo, and the rotation of the cone bottom makes the material not easy to arch and bridge, which is widely used in power plants and chemical plants

VIEW MORE +BLT series Factory Direct Sale Chain Plate Conveyor Bulk material Handling Equipment

BLT series apron conveyor, traction chain adopts sleeve roller chain. In addition to materials with particularly large viscosity, general solid materials and finished items can be transported.

VIEW MORE +SDB(F) series Professional Manufacturer Chain Bucket Conveyor for Large granular material handling

SDB(F) series chain bucket conveyor, traction chain adopts sleeve roller chain, continuous bucket structure, applicable to all kinds of normal temperature, high temperature powder or small block loading materials. Horizontal or inclined brush dragon, large Angle (up to 75 degrees) conveying.

VIEW MORE +